Shopping for heavy-duty nylon webbing straps can feel like rummaging through a yard-sale pile of specs. One listing flaunts a “10,000-pound” tensile rating, another whispers “craft grade only,” and almost none explain whether those numbers match your real-world load. “Heavy duty” is just marketing—no universal standard backs the claim. What matters is how your load sits, moves, and cycles—and whether you’re buying raw webbing or a factory-finished strap. Use the 15 checks below to cut the fluff, choose with confidence, and keep your gear secure.

When off-the-shelf straps miss the mark

Professionally bar-tacked heavy-duty straps and raw nylon webbing show the difference between finished tie-downs and ribbon on a roll.

Cutting a longer strap to size sounds simple, until the first hard tug pops a home-sewn seam. Industrial bar-tack machines clamp layers with 3,500–4,500 lbf (about 15.6–20.0 kN) of holding power, a level no consumer machine can touch. If your roof-rack cradle or DIY cargo box needs a length the shelf doesn’t stock, order a professionally finished strap instead.

One option is the Country Brook Crafts custom strap service. You email width, length, and hardware specs and receive bar-tacked, heat-sealed straps ready to pull. Any reputable shop should match the same minimums:

Published tensile and working load limit data (per WSTDA-T-1 tie-down guidance)

Heat-sealed edges with no loose yarns

A clear turnaround window before you click “Buy”

Secure the custom length first, then work through the fifteen upgrade checks that follow to decide whether you truly need heavy-duty webbing or if standard strength will do.

Where to order custom straps & webbing

If you’ve already nailed down your width, length, and hardware, these shops can fabricate straps or supply custom webbing—just make sure you still ask for WLL / breaking strength info when you’re buying for cargo securement.

Country Brook Crafts (best for: custom cut & sewn webbing products + printed webbing)

Country Brook’s custom service covers custom cutting & sewing for webbing products, plus dye-sublimation for flat webbing and laser engraving—a solid fit for makers and brands who want straps/webbing built to spec (and often with design/branding needs).

Strapworks (best for: custom webbing printing + strap fabrication)

Strapworks offers custom webbing printing and strap fabrication, aiming to produce “exactly the product you need” when off-the-shelf straps don’t fit your use case.

US Cargo Control (best for: made-to-order ratchet straps with lots of configuration)

US Cargo Control specializes in custom ratchet straps with configurable webbing color/width/length, end fittings, custom stenciling, and tags, assembled on-site in their Iowa facility.

Cargo Control USA (best for: dealers/industrial buyers needing capacity ranges + private label)

Cargo Control USA notes they can help design custom products, and they outline both light-duty strap capacities and heavy-duty assemblies (plus private labels/stenciling and custom colors)—useful if you’re sourcing for fleet/trucking channels.

Northwest Straps (NW Straps) (best for: branded/custom tie-downs, lanyards, webbing—wholesale friendly)

NW Straps positions itself as an American manufacturer for custom branded tie-downs and related strap/webbing products, with a stated made-to-order lead time (up to ~12 weeks)—better for planned runs than urgent one-offs.

Upgrade check #1 – static load or moving target?

Picture two Saturdays. First, you cinch a kayak to roof bars for a smooth highway cruise. Second, you strap a toolbox to an open trailer that rattles over potholes for 200 miles (about 320 km). The kayak ride stays mostly static; once tensioned, the strap hardly feels a jolt. The trailer run becomes a rolling tug-of-war.

Why it matters: nylon webbing stretches about 5 to 7 percent at its rated load, acting like a built-in shock absorber that softens sudden spikes. Polyester stretches roughly half as much—about 2 to 3 percent—so it keeps steady tension but passes vibration straight to stitches and hardware.

Rule of thumb

Jerks, jolts, or stop-start motion (dirt-bike tie-downs, ladder racks on rough roads) → nylon absorbs shock.

Constant pull with little vibration (roof-top kayak on smooth highways, garage hoists) → polyester stays tight and adds UV stability.

Match the fabric to the ride, not the marketing label.

Upgrade check #2 – do you need the working load limit, not just tensile strength?

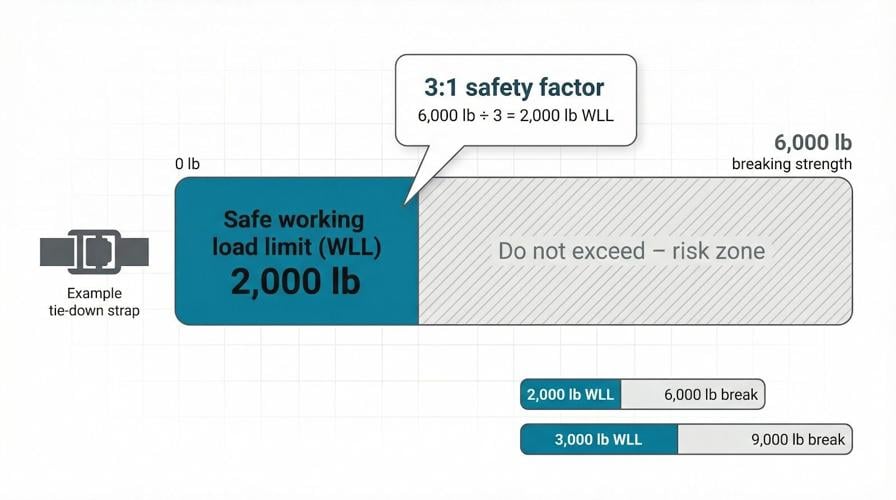

A product page might trumpet “6,000-pound breaking strength.” Sounds solid, until you remember that breaking strength is a one-and-done lab number: the force that snaps a brand-new sample. In service, we rely on the working load limit (WLL), the highest force you should ever apply.

For synthetic web tie-downs, the Web Sling & Tie Down Association and most catalog makers use a 3 to 1 design factor. Divide the lab figure by three and you get the safe number:

6,000 lb (about 2,720 kg) ÷ 3 = 2,000 lb (about 910 kg) WLL.

A strap’s breaking strength is a lab number—always size your tie-downs by the lower working load limit.

If a listing hides the WLL, move on. A reputable maker shares the spec that protects your gear and your Saturday plans. Remember, lifting slings and overhead rigging follow stricter 5 to 1 or higher factors, so always match the standard to your job before trusting any strap.

Upgrade check #3 – run the three-to-one reality check

WSTDA-T-1, the industry standard for synthetic tie-downs, says a strap’s working load limit (WLL) must equal at least one-third of its minimum breaking strength. That 3 : 1 safety factor absorbs wear, nicks, UV aging, and those “just cinch it tighter” moments every strap faces.

Quick math: a strap advertised at 9,000 lb (about 4,080 kg) break strength should list a WLL of 3,000 lb (about 1,360 kg). Compare that number—not the headline rating—to your heaviest expected pull. If the math falls short, size up or double up. You wouldn’t stuff a backpack to triple its rated capacity, so don’t ask a strap to do it either.

Upgrade check #4 – are you buying raw webbing or a finished strap?

Scroll any marketplace and you’ll spot a two-inch “heavy nylon strap” beside a two-inch “heavy nylon webbing.” They sound interchangeable, yet the first ships with sewn loops and hardware, while the second is just ribbon on a roll.

Raw webbing on a roll (left) versus a finished strap with bar-tacked hardware (right) shows why “heavy nylon webbing” and “heavy nylon strap” are not the same purchase.

Raw webbing only makes sense if you own an industrial machine, 40-weight bonded thread, and the skill to run box-X or multi-bar-tack patterns that test engineers rate at 3,500 to 4,500 lbf (about 15.6 to 20.0 kN) per joint. Most home machines stall near 500 lbf (about 2.2 kN), so the seam, not the webbing, fails first.

If you can’t point to the tool that delivers a certified seam, choose the finished strap. Spending a few dollars more up front saves a Saturday’s work and removes the risk of a mid-drive unravel.

Upgrade check #5 – does the strap width match your hardware and the load?

Width isn’t cosmetic; it sets both capacity and fit. A 2-inch (50 mm) tie-down typically carries a working load limit between 1,500 and 3,333 lb (about 680 to 1,510 kg). Pair it with a 1.5-inch cam buckle and the resulting fold will saw at the fibers and slash that capacity.

Quick rule

Webbing width = hardware width = surface you’re protecting. Measure the slot in your buckle or ratchet, then choose the strap that fills it edge to edge. Your gear, and the webbing, will last longer when every piece plays the same width game.

Upgrade check #6 – is thickness doing the heavy lifting or is the label just loud?

Ignore “mil-spec,” “super duty,” and other hype words. Check the spec sheet instead. A 2-inch (50 mm) nylon at 0.08 inch (about 2 mm) thickness typically breaks around 4,000 to 5,000 lb (about 1,810 to 2,270 kg). The same width at 0.12 inch (about 3 mm) can reach 6,000 lb (about 2,720 kg), a gain of more than 40 percent. Thicker webbing packs more yarn, which raises break strength and extends abrasion life.

So compare the decimals, not the adjectives. If a seller won’t list thickness, that silence speaks louder than any marketing copy.

Upgrade check #7 – flat or tubular: which weave wins your job?

Run a finger across flat webbing and you feel a belt-like ribbon. Trace tubular webbing and it feels like a soft hose; the fibers fold into a hollow sleeve.

Performance numbers back up the tactile cues. In ASTM D4157 abrasion tests, 1-inch (25 mm) tubular nylon survived 15,000 to 25,000 cycles before losing half its strength, while standard flat endured only 5,000 to 10,000 cycles. Yet high-spec flat types such as MIL-W-4088 Type 7 can reach 6,000 lb (about 2,720 kg) breaking strength, well above generic tubular’s 4,000 lb (about 1,810 kg).

Choose flat when the strap will slide over racks, brick edges, or pallets and you can spec a premium, abrasion-rated tape.

Choose tubular when you need tight bends, girth hitches, or extra edge protection around irregular shapes.

Match the weave to the task, not the marketing label.

Upgrade check #8 – will the sun cook your straps before the job is done?

Nylon loves shade. Leave it on a roof rack for three full summers and lab tests show it can lose 50 to 60 percent of its tensile strength to UV alone, as the fibers fade and stiffen. Polyester loses about 30 percent early on, then levels off, keeping the rest of its strength much longer under the same exposure.

That swing matters. A kayak tie-down baked on your car, a patio-cover strap, or a rooftop-tent ladder shouldn’t drift toward half strength just because seasons change. If the webbing will live outdoors, choose polyester. Save nylon for shaded garages, indoor gym rigs, or quick weekend trips where UV hours stay low.

In short: sunlight favors polyester; shade lets nylon thrive.

Upgrade check #9 – will water change how your strap behaves?

Nylon absorbs roughly four to five percent of its own weight in water, while polyester takes up only about 0.4 percent. That added moisture makes nylon fibers swell and stretch under load, trimming the working load limit until they dry.

Use-case lens

Roof-rack surfboards, dock lines, or SUP carriers can benefit from nylon’s extra five to six percent stretch, if you’re willing to retension after every dunk.

For set-and-forget jobs such as patio covers or trailer tie-downs that stay wet overnight, polyester keeps its original length and dries in under an hour, saving you nightly checks.

Match the material to the forecast, and your gear stays snug whether it’s a drizzle or a dunk.

Upgrade check #10 – will sharp edges chew through your strap before the day ends?

Even a 6,000-lb (about 2,720 kg) strap can fail after a few hundred abrasion cycles across a steel edge. ASTM D6770 tests show flat nylon webbing can lose more than thirty percent of its breaking strength after just 1,000 cycles on a 90-degree bar. One pothole later, and those weakened fibers can part.

Protection, not extra thickness, fixes the problem. Slip-on edge guards, wear sleeves, or even a short length of garden hose move the rub point off the load path. Inspect contact spots before you cinch: fresh paint chips, brick dust, or flattened fibers mean the strap is already wearing down. Shield the edge first, then tighten the strap.

Sharp corners can chew through even strong straps. A simple wear sleeve or hose over the edge protects your tie-downs and your load.

Upgrade check #11 – is the stitching up to the same standard as the webbing?

A strap is only as strong as its weakest inch, and that inch is usually the sewn joint. In destructive-pull tests, a proper bar-tack on 2-inch nylon holds about 3,500 to 4,500 lb (roughly 1,590 to 2,040 kg) before tearing. Look for tight, symmetrical bar-tacks: rows of stacked zigzags that resemble railroad ties. Skipped threads, uneven spacing, or loose tails signal rushed production and lower capacity.

Industrial machines drive bonded polyester or nylon thread into the webbing with several thousand pounds of clamp force, something a home “heavy-duty” machine can’t match. For any load moving faster than traffic or hanging overhead, trust factory-sewn bar-tacks. A strong weave deserves a stitch that matches its rating.

Upgrade check #12 – will rust, salt, or chemicals eat your hardware before your next trip?

Webbing never works alone; buckles, hooks, and ratchets carry the load. Corrosion testing shows why alloy choice matters. In a neutral salt-spray chamber (ASTM B117):

Electro-galvanized (basic zinc-plated) steel shows red rust after roughly 100 to 250 hours.

Hot-dip galvanized or thick zinc coating can last 500 hours or more but still stains in coastal spray.

304 or 316 stainless steel routinely exceeds 1,000 hours with no red rust.

Aluminum hardware cuts weight, which is handy for backpack gear, but untreated aluminum can pit in road-salt brine and may dent if you over-torque the cam.

Match metal to environment: use stainless on boat trailers, dock straps, or winter roof boxes. Save plated steel for indoor gym rigs or weekend camping when budget matters. Choose the alloy that keeps every click and cam as strong as the webbing that feeds it.

Upgrade check #13 – are you about to use the strap for something it was never designed to do?

Tie-down straps secure cargo. Recovery straps free stuck vehicles. They’re cousins, not twins. A nylon recovery “snatch” strap is built to stretch about twenty percent, storing kinetic energy for a controlled yank, while a polyester tie-down stretches only two to three percent and is engineered for steady tension. Mixing the two jobs can shred stitches and launch hardware like shrapnel. The U.S. Fish & Wildlife Service even bans using tie-down chains for other tasks because hidden damage weakens their rated strength.

The same logic applies to life-safety loads. Hoisting a platform, hanging a swing, or rigging climbing anchors calls for gear stamped with UIAA, ANSI, or OSHA ratings, not a generic “heavy duty” tag. If people or vehicles hang in the balance, reach for purpose-built equipment and leave cargo straps in the toolbox where they belong.

Upgrade check #14 – are you trusting furniture safety to a no-name strap?

Tip-overs send an estimated 11,500 children to U.S. emergency rooms each year, according to Consumer Product Safety Commission (CPSC) data. On September 11, 2025, the agency warned families to stop using Cranach plastic tip-restraint kits after 115 breakages and six reported tip-overs; the product failed ASTM F3096-23 strength tests.

Takeaway: straps that anchor dressers or TVs must meet ASTM F3096-23 (tip restraints) or appear on a STURDY-compliant list, and that compliance should be printed on the package. If the kit in your cart lacks a standards call-out, skip it. Certified metal kits cost only a few dollars more, install in minutes, and remove a life-altering risk. For home safety, buy the proof, an ASTM label, not a marketing promise.

Upgrade check #15 – does paying more now save you replacements later?

Cost per year tells the truth. Here’s a quick example based on average Amazon pricing captured in June 2025:

Strap type | Pair price | Avg. service life* | Cost per year |

Light nylon, zinc cams | USD 20 | 1 year | USD 20 |

Heavy nylon, stainless cams | USD 40 | 4 years | USD 10 |

*Service life estimates pulled from 1,200+ buyer reviews across five leading listings (average roof-rack use, moderate sun exposure).

Over the same four-year window you would spend USD 80 on the bargain set versus USD 40 on the upgrade, while avoiding two mid-trip replacements. Add the hidden costs of a damaged kayak or an unplanned hardware-store detour, and quality wins by an even wider margin.

Pay for lifespan, not just the click price, and your straps will stay off the shopping list—and out of the landfill—far longer.

Quick-glance guide: which strap fits your job?

Scenario | Best webbing | Key add-ons | Why it wins |

Moving or garage tie-downs | 2-inch nylon ratchet strap | Zinc ratchet + stitched loop | 5–7 percent stretch cushions bumps; ratchet speeds repetitive loads |

Outdoor storage or patio covers | 1- to 2-inch polyester with stainless cam | UV-rated thread | Loses about 30 percent strength after years of sun, resists rust |

Roof-rack hauling | 1.5- to 2-inch nylon tie-down (WLL on label) + edge guard | Rubber wear sleeve | Absorbs shock loads; guard blocks brick or bar abrasion |

DIY leashes or camera straps | ¾-inch tubular nylon | Lightweight aluminum triglides | Tubular weave feels softer on skin yet tests more than 4,000 lb (about 1,810 kg) break strength |

Pick the row that mirrors your project, then use the fifteen upgrade checks to dial in width, thickness, and hardware.

What to ask before you buy: copy-and-paste checklist

Webbing width and thickness

Material blend and weave type (flat or tubular)

Published minimum breaking strength and working load limit

Safety factor used to convert break strength to WLL

Test method plus date of most recent certification

Hardware alloy, corrosion treatment, and coating thickness

Whether the roll is continuous or has splices

Lead time, return policy, and price break for multiples

If a supplier can’t answer in one email, find one who can.

Care, inspection, and retirement: keeping straps strong year after year

A strap wears out by cycles, not calendar pages. FMCSA cargo-securement guidance says to inspect tiedowns at the start of every trip and replace any that show cuts or abrasion exceeding ten percent of webbing width (49 CFR §393.104). Use that threshold as your baseline.

Regular hands-on inspections and dry, shaded storage help you retire damaged straps before they drop a load.

Quick check routine:

Run your fingers the full length. Feel for cuts, heat glazing, or stiff spots that hint at chemical damage.

If you see fuzzy edges or a single pulled thread, trim and melt-seal, then recheck after the next run.

Retire the strap right away if white core fibers show, stitches are half-gone, or glazing covers more than a dime-sized area (about 18 mm).

Storage matters: hang straps loose, out of sunlight, and completely dry. Lab tests show mildew can cut nylon strength by up to fifteen percent in three months of damp storage (USDA Forest Products study 2019).

Tag each strap with purchase and first-service dates. Heavy users often set a two-season cap (about 200 to 250 tension cycles), even if no damage is visible, because that small habit costs far less than a dropped load.

Replace early, track cycles, and your webbing will end its life in the trash can, never on the road.

Post a comment as Guest

Report

Watch this discussion.

(0) comments

We welcome your comments

Log In

Post a comment as Guest

Keep it Clean. Please avoid obscene, vulgar, lewd, racist or sexually-oriented language.

PLEASE TURN OFF YOUR CAPS LOCK.

Don't Threaten. Threats of harming another person will not be tolerated.

Be Truthful. Don't knowingly lie about anyone or anything.

Be Nice. No racism, sexism or any sort of -ism that is degrading to another person.

Be Proactive. Use the 'Report' link on each comment to let us know of abusive posts.

Share with Us. We'd love to hear eyewitness accounts, the history behind an article.