Manufacturers lose their millions in terms of damaged products in transit every year. In industries where finesse is of utmost importance, such as in the automotive sector, electronics, and the medical device industry, such minor damages can translate to rejected batches, rework with high cost, and a slow supply chain.

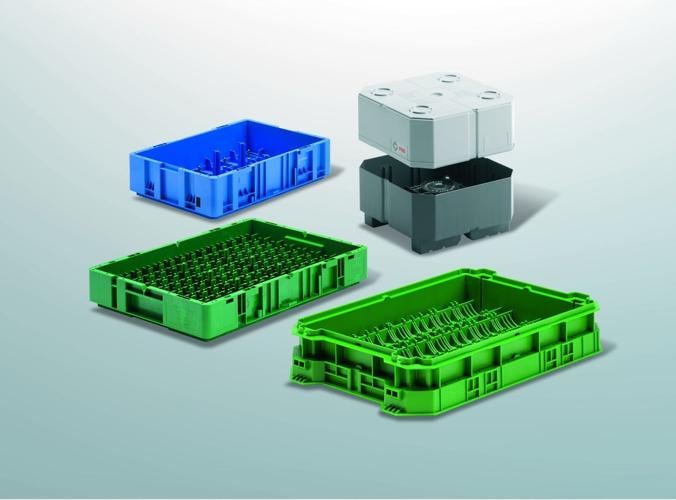

As a solution to this, many manufacturers are resorting to thermoformed workpiece carriers, which are specially designed transit protection packaging that envelop the products in a more precise fashion. These thermoformed plastic containers have been viewed as an important element of the contemporary logistics setup by integrating precision molding, material science, and customized design.

Why Micro-Movement Happens Even in “Secure” Packaging

The most meticulously packed product is in constant motion when transporting. Micro-movement is the movement when the elements within the packaging rub, slide, or bounce on surfaces or within the packaging against one another or their surfaces.

Micro-movement can be explained by several factors:

- Vibration

- Loose fit

- Compression of material

- Thermal expansion

Minor flaws in the transit protection packaging design may cause a lot of magnification during long-distance transportation. The result? Scripped surfaces, broken finishes, bent connections, or scratches so minute that they undermine the quality of the product.

What Makes Thermoformed Workpiece Carriers Different

Thermoformed workpiece carriers bring a certain degree of accuracy and stability, which traditional packaging is unable to replicate.

The main benefits of thermoformed workpiece carriers are:

- Precision custom-fit: When the cavity is designed to fit the product, every cavity will be designed to fit precisely and repeatedly.

- Dimensional stability: Rigid plastics do not change shape when pressured or when changes in temperature occur, as is the case with foam or cardboard.

- Material versatility: Workpiece carriers are available in many materials, depending on the required balance of strength, weight, and cost.

- Stackability: Workpiece carriers are made to be nestable or stackable, so as to take minimal space when transporting and in storage.

- Cleanroom readiness: A wide range of thermoformed workpiece carriers can be manufactured using materials that can be used in sterile cleanrooms.

Packaging for electronics does not merely come in a single style, but it also fits perfectly in automated handling and assembly lines.

How Thermoformed Workpiece Carriers Actively Prevent Micro-Movement

Custom packaging workpiece carriers are effective because they can regulate and reduce movement on a variety of levels. They do not have to depend on cushioning alone, but rather, they apply structural precision so that the conditions under which micro-movement may take place at all are eliminated.

Contour-Fitting Cavities

Every product is placed in a cavity in which it is designed to fit, limiting movement in every direction. No play or gap there either- just a tight fit that keeps the part in place even when the package is turned upside down or rocked about.

Fixed Support and Distribution of Load

Thermoformed materials evenly spread external forces in the packaging surface, avoiding any pressure points, which may bend or move parts.

Friction at the Surface and Choice of Material

The texture of the surface and the material content can be designed to be more frictional so that there is less sliding. Delicate surfaces can also be protected with ESD-safe materials or soft, low-abrasion surfaces designed specifically for sensitive components.

Stacking and Alignment Security

The workpiece carriers are also designed to lock each other as they are stacked, and they do not shift when transported in bulk. This not only provides stability of individual parts but also a shipment.

Returnable Systems Compatibility

A lot of thermoformed workpiece carriers are redesigned to be reused and become part of closed logistic networks. 46% of plastic packaging ends up in landfill. This solution provides a steady positioning of the parts whilst working alongside business sustainability expectations.

Companies like Utz Group are offering returnable packaging systems with dimensional consistency throughout the years of use, and waste is minimized, as well as part protection between the supplier's dock and assembly line.

Choosing the Right Design for Your Product

The important factor to ensure maximum use of thermoformed workpiece carriers is that a proper design should be chosen to suit your product and process. The fact that items are different in the sense of size, shape, fragility, and finishing renders the solution to be non-uniform.

The following factors should be considered when choosing a thermoformed workpiece carrier:

- Product geometry: The packaging should adhere to the outlines of the part, and in particular when the part is irregular or asymmetrical.

- Selection of materials: Select materials that are the right rigidity, chemical resistant, and temperature tolerant. In the case of electronics or cleanroom products, it can be necessary to use anti-static or non-shedding materials.

- Handling process: In automated systems, dimensional accuracy and repeatability are important in case of using workpiece carriers.

- Stacking and nesting needs: Stacking the product requirements would save on space requirements, transportation costs, and also preserve product security.

- Green factor: Reusable and recyclable products can help with the sustainability objectives and reduce expenses in the long term.

The design of a good thermoformed component holds not only protects but also becomes a component of the whole production system, allowing automation, productivity, and consistency throughout the supply chain.

Micro-movement damage can be unseen at the surface level, yet its impact on quality, yield, and cost cannot be denied. The solution to this problem is custom thermoformed workpiece carriers, which are scientifically designed and help in solving this issue at its origin. They combine the accuracy of molding and the durability of materials to make sure that the components are absolutely stable even during long-distance transportation.

Post a comment as Guest

Report

Watch this discussion.

(0) comments

We welcome your comments

Log In

Post a comment as Guest

Keep it Clean. Please avoid obscene, vulgar, lewd, racist or sexually-oriented language.

PLEASE TURN OFF YOUR CAPS LOCK.

Don't Threaten. Threats of harming another person will not be tolerated.

Be Truthful. Don't knowingly lie about anyone or anything.

Be Nice. No racism, sexism or any sort of -ism that is degrading to another person.

Be Proactive. Use the 'Report' link on each comment to let us know of abusive posts.

Share with Us. We'd love to hear eyewitness accounts, the history behind an article.