Picture a crane lowering pre-cut timber beams into place before your coffee cools. Factory-built shells now trim cabin costs by 20–40 percent and arrive weather-tight in just two to eight weeks (Beachy Barns). According to Energy Geeks, that speed lands just in time for the stricter energy-code updates taking effect January 2026, which tighten insulation and blower-door targets nationwide. Builders such as Hamill Creek Timber Homes already leave space for thick SIP wraps to meet those rules. Below, we rank seven prefab timber-frame providers so you can choose the one that matches your budget, timeline, and style.

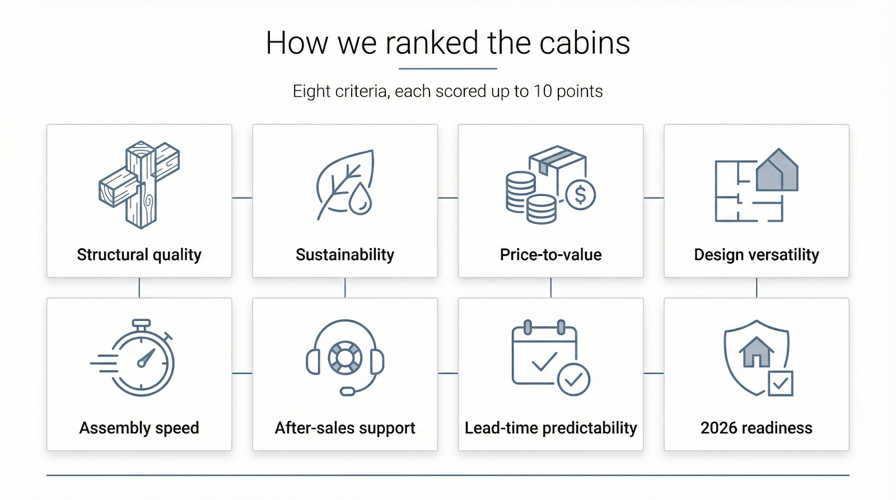

How we ranked the cabins

A prefab timber frame cabin shell being craned into place, illustrating how factory-built frames speed up cabin projects.

We graded each company across eight categories, assigning up to 10 points per category for a maximum score of 80.

Eight scoring criteria—from structural quality to 2026 readiness—behind our prefab timber frame cabin rankings.

The eight criteria

Structural quality – lumber grade, joinery method, and stamped engineering plans

Sustainability – certified wood, low-carbon envelopes, and energy performance

Price-to-value – scope of materials in the crate compared with total cost

Design versatility – breadth of footprints and customization choices

Assembly speed – calendar days from truck arrival to a weather-tight shell

After-sales support – clarity of manuals, phone help, and optional set-crew assistance

Lead-time predictability – months between deposit and confirmed delivery window

2026 readiness – alignment with the stricter energy and wildfire codes effective January 2026

If two companies tied, we favored the one with the shorter lead-time and confirmed our rankings against owner reviews plus third-party case studies. The result is a list you can rely on when you’re ready to place a deposit.

1. Hamill Creek Timber Homes

Each frame is test-fit under a crane, labeled, and shipped anywhere in the United States.

A timber frame cabin by Hamill Creek Timber Homes, our top-ranked prefab provider for long-lived showpiece cabins.

What you can order

Custom timber frame kit – structural skeleton, about $60–$90 per sq ft for materials only

Lock-up shell – frame plus SIP or stud walls, roof panels, windows, and exterior doors

Turnkey build – Hamill Creek’s crew finishes the cabin on-site; completed projects usually land in the $300–$500 per sq ft range

Designers leave cavity depth for 8-inch SIPs or dense-pack mineral wool so the cabin meets the stricter 2026 energy code without retrofits. According to Hamill Creek Timber Homes’ timber enclosure and energy-efficiency guides, timber frame SIPs can achieve high thermal values and help save up to 50 percent of heating and cooling costs compared with traditional fiberglass insulation, while built-up roof systems add fire and uplift performance along with extra weather protection. Optional metal roofing and fiber-cement siding satisfy wildfire rules for western WUI zones, and because the timber frame carries the load, interior walls can be repositioned later, which is helpful if life or rental layouts change.

Why it tops our list

Hamill Creek scores high for structural quality, sustainability (FSC-certified Douglas-fir, spruce, or western red cedar), and 2026 readiness. The trade-off is cost and the need for a skilled crane crew, yet if you want a long-lived, code-compliant showpiece, this Canadian builder sets a clear benchmark.

2. Unity Homes

Founded by timber-frame pioneer Tedd Benson, Unity Homes turns CNC-cut panels into Passive House-level shells that crews bolt together in as little as three days. Each wall or roof cassette leaves the New Hampshire factory dense-packed with cellulose, pre-wired, and fitted with triple-pane windows, so weather cannot stall the build.

A high-performance prefab home from Unity Homes, our pick for Passive House-level cabin shells ready for 2026 energy codes.

Performance is the headline: a standard Unity home posts a HERS score near 40, about 60 percent more efficient than a code-built house. The 1 159 sq ft Xyla Lugn shell lists at $180 000 and finishes at $430 000–$490 000, while the 1 835 sq ft Xyla Mys shell is $315 000 with a $745 000–$845 000 finished range, slab included.

Unity sticks to five core footprints yet offers dozens of finish palettes, keeping timelines predictable—typically six to seven months from deposit to move-in. If you want a cabin that already meets the tougher 2026 energy code and can reach net-zero with a rooftop PV array, Unity delivers precision without architectural drama.

3. PrecisionCraft Log & Timber Homes

PrecisionCraft treats mountain cabins like couture. In the company’s Meridian, Idaho shop, artisans hand-select western red cedar or Douglas-fir logs, sculpt each saddle-notch by eye, and pre-fit the entire shell before it ships to your site. You collaborate with sister firm M.T.N Design to frame views, rooflines, and hidden bunk rooms. Every log is modeled in 3-D, cut, numbered, and later restacked by a PrecisionCraft crew to create a lodge-grade shell.

A handcrafted log-and-timber cabin by PrecisionCraft, ideal for buyers who want couture-level mountain lodge cabins built to modern codes.

Cost mirrors the craftsmanship. Published budgets for turnkey builds usually start around $300–$400 per sq ft, with handcrafted log projects at the upper end. Planning is lengthy: allow about nine months from first design meeting to material delivery and another 6–18 months for onsite construction, depending on complexity and local labor.

What you gain is generational durability. Massive logs shrug off heavy snow, char slowly in wildfire conditions, and meet modern codes. Hybrid log and SIP packages add the insulation needed for 2026 energy targets. If you can invest the money and the months, PrecisionCraft delivers a statement home that feels carved from the landscape rather than delivered to it.

4. Zook Cabins

If speed tops your wish list, Zook Cabins delivers. Amish crews in Lancaster County, Pennsylvania build each park-model or two-section modular cabin indoors, complete the interior, and ship the finished modules to your site. A crane sets them in place, and the structure is weather-tight the same day; Zook’s delivery guide shows most installs finished in eight hours or less.

A park-model prefab cabin from Zook Cabins, built indoors and delivered to your site for same-day setup.

That pace can shave months of interest off a construction loan and launch rental income sooner. Inside, you still get real-wood character: knotty-pine walls, solid cabinetry, and upgrades such as stone fireplaces or wrap-around porches. Current pricing lists single-wide park models like the 400 sq ft Settler from $79 900 delivered, while two-bedroom modular cabins of roughly 960 sq ft run $145 000–$165 000 with appliances installed.

The compromise is scale. Highway limits keep each module under about 14 ft wide, so soaring great rooms require creative layouts. Energy performance meets standard IRC levels, and buyers can add options such as spray-foam floor insulation, metal roofs, and ember-resistant vents to satisfy the 2026 energy and wildfire codes.

For weekend retreats, ADUs, or a quick fleet of rental units, Zook’s drive-and-drop cabins turn the “someday” project into a first-quarter reality.

5. DC Structures

DC Structures bridges the gap between a do-it-yourself lumber package and a full turnkey build. At the company’s Portland-area plant, crews CNC-cut each Douglas-fir post, label every stud, and bundle windows, siding, fasteners, and metal roofing into one shipment.

A kit-built cabin from DC Structures, offering a middle ground between DIY lumber packages and full custom timber frames.

Choose a catalog plan, such as the 1 009 sq ft Gearhart A-frame (kit from $153 000) or the barn-style Sunriver at 1 885 sq ft (kit from $179 000). Adjust roof pitch, add a porch, or swap cedar for board-and-batten; revised drawings return with an engineer’s stamp, so most permit offices approve them without changes.

When the trucks arrive, a small crew can dry-in the shell in about three to five weeks, according to DC’s case studies and builder FAQs. Finished costs usually land between $220 and $280 per sq ft, comfortably below many custom timber frames.

Energy code upgrades are simple. Order SIP roof panels or specify 2 × 8 walls for R-30 cavity insulation and the package ships ready for blower-door testing. For owners who want creative control without tracking down every board, DC offers a well-documented middle lane.

6. Timberlyne

Timberlyne, known until 2022 as Sand Creek Post & Beam, delivers true post-and-beam kits cut on CNC saws in Wayne, Nebraska. Packages pair 8 × 8 timbers with steel plate joinery, board-and-batten siding, and porch-ready overhangs that evoke century-old farmsteads.

A Timberlyne loft-living barn home, combining 8×8 post-and-beam structure with farmstead-inspired board-and-batten siding.

You start with a base plan such as an A-frame, gambrel barn home, or wrap-around ranch, then meet online with a designer to stretch a loft, add a gear garage, or move windows. Revised, engineer-stamped drawings usually return within two weeks and are calibrated to your site’s wind and snow loads.

The kit ships shrink-wrapped and numbered; a local crew can dry-in a 1 728 sq ft Lexi loft-living model in three to five weeks, according to the Timberlyne builder guide. Shell kits begin around $100 per sq ft, while national-average turnkey costs run about $250 per sq ft for loft-living versions. Owners can specify 2 × 8 walls and foam-filled roof panels to meet 2026 energy-code R-values, and metal roofs plus ember-resistant vents are available for wildfire zones.

Some stewardship is required: re-stain exposed pine or cedar every three to five years and snug bolts after the first heating season. Handle those simple tasks, and the frame’s cathedral ceilings and front porch should weather decades of sunsets without a luxury-builder price tag.

(0) comments

We welcome your comments

Log In

Post a comment as Guest

Keep it Clean. Please avoid obscene, vulgar, lewd, racist or sexually-oriented language.

PLEASE TURN OFF YOUR CAPS LOCK.

Don't Threaten. Threats of harming another person will not be tolerated.

Be Truthful. Don't knowingly lie about anyone or anything.

Be Nice. No racism, sexism or any sort of -ism that is degrading to another person.

Be Proactive. Use the 'Report' link on each comment to let us know of abusive posts.

Share with Us. We'd love to hear eyewitness accounts, the history behind an article.