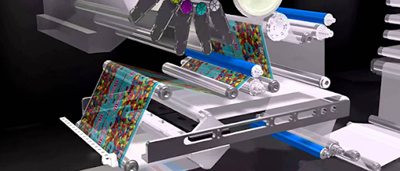

Flexographic printing plays a crucial role in the food and beverage industry, providing high-quality and visually appealing packaging for various products. However, when using flexographic printers in this industry, there are important compliance and safety considerations that must be addressed. In this article, we will explore the compliance requirements and safety considerations specific to flexographic printing in the food and beverage industry.

Compliance with Food Safety Regulations

Compliance with food safety regulations is of utmost importance when using flexographic printing in the food and beverage industry.

FDA Regulations: The U.S. Food and Drug Administration (FDA) regulates packaging materials that come into direct contact with food. Flexographic printers must ensure that the inks, substrates, and other materials used in the printing process comply with FDA regulations to prevent contamination and ensure food safety.

Migration Testing: Flexographic printers should conduct migration testing to ensure that no harmful substances from the packaging materials migrate into the food or beverage products. This testing helps verify compliance with regulations and ensures the safety of the end consumers.

Compliance Documentation: Flexographic printers should maintain comprehensive documentation related to compliance with food safety regulations. This includes documentation of the materials used, their safety certifications, and the results of any migration testing performed.

Safe Handling of Printing Inks and Chemicals

Safe handling of printing inks and chemicals is essential to protect workers' health and minimize environmental impact.

Material Safety Data Sheets (MSDS): Flexographic printers must have access to MSDS for all printing inks and chemicals used in the printing process. MSDS provides critical information regarding the potential hazards, safe handling procedures, and emergency response measures in case of accidental exposure.

Personal Protective Equipment (PPE): Workers involved in flexographic printing should wear appropriate PPE, such as gloves, safety glasses, and protective clothing, to minimize the risk of skin contact or inhalation of chemicals. Adequate ventilation systems should also be in place to reduce exposure to hazardous fumes.

Proper Storage and Disposal: Printing inks and chemicals should be stored securely in suitable containers and under appropriate conditions to prevent spills, leaks, or cross-contamination. Dispose of any waste materials, including used ink containers and cleaning solvents, in accordance with local regulations and best practices.

Quality Control and Traceability

Maintaining quality control and traceability is essential for ensuring compliance and safety in the food and beverage industry.

Quality Management Systems: Implementing robust quality management systems helps ensure the consistent production of safe and compliant packaging. This includes regular inspections, process control measures, and adherence to industry standards for flexographic printing.

Lot and Batch Control: Establishing clear lot and batch control procedures enables traceability of packaging materials and identifies potential issues. Flexographic printers should clearly label and document each print run or batch to facilitate product recalls and address any quality or safety concerns.

Supplier Audits and Qualification: Flexographic printers should conduct thorough supplier audits and qualification processes to assess the compliance and safety practices of their ink and substrate suppliers. Regular evaluations ensure that all materials used in the printing process are sourced from reputable and compliant vendors.

Training and Education

Providing adequate training and education is vital to ensure safety and compliance in flexographic printing.

Safety Training: All employees involved in the printing process should receive comprehensive safety training on the proper handling, storage, and disposal of inks, chemicals, and packaging materials. This training should also include emergency response procedures.

Regulatory Updates: Flexographic printers should stay updated on the latest regulations regarding food safety, packaging materials, and printing inks. This knowledge ensures compliance with changing requirements and helps identify opportunities for process improvement.

In conclusion, when utilizing flexographic printing in the food and beverage industry, compliance with food safety regulations and attention to safety considerations are paramount. Ensuring compliance, safe handling of inks and chemicals, maintaining quality control, and providing proper training are vital to protect consumer health, minimize environmental impact, and meet industry standards. Flexographic printers must prioritize these considerations to deliver high-quality and safe packaging solutions that meet the stringent requirements of the food and beverage industry.

(0) comments

We welcome your comments

Log In

Post a comment as Guest

Keep it Clean. Please avoid obscene, vulgar, lewd, racist or sexually-oriented language.

PLEASE TURN OFF YOUR CAPS LOCK.

Don't Threaten. Threats of harming another person will not be tolerated.

Be Truthful. Don't knowingly lie about anyone or anything.

Be Nice. No racism, sexism or any sort of -ism that is degrading to another person.

Be Proactive. Use the 'Report' link on each comment to let us know of abusive posts.

Share with Us. We'd love to hear eyewitness accounts, the history behind an article.